Get our last news and exclusive informations about our products

Know-How & innovations

LUXURY HANDCRAFT

For the past 40 years, TRIANGLE has been designing and assembling its prestigious speakers in our workshop in Soissons. Our team of engineers works closely with production, thus ensuring unparalleled manufacturing quality and compliance with very precise and detailed specifications.

TRIANGLE’s traditional craftsmanship is based on our employees’ expertise, brought about from many years of experience, some of whom have been with the company for more than 35 years. The different components are controlled and carefully assembled, to achieve the utmost finish and acoustic quality.

FRENCH Manufacture

Created in 1980 by Renaud de Vergnette in Soissons, TRIANGLE has proudly shown the world its passion for sound reproduction devices for the past 40 years.

With products manufactured in Soissons in Picardy, TRIANGLE legitimately claims to be Made in France. Each speaker is controlled and stamped in our workshops, benefitting from a dedicated production follow-up tracing the origin of each component.

CONCEPTION

In the quest for innovation, the R&D team of TRIANGLE has developed new components. Each aspect of this 40th Anniversary Edition is the result of a careful optimization effort. Nothing has been left to chance, for a single purpose: sharing emotions

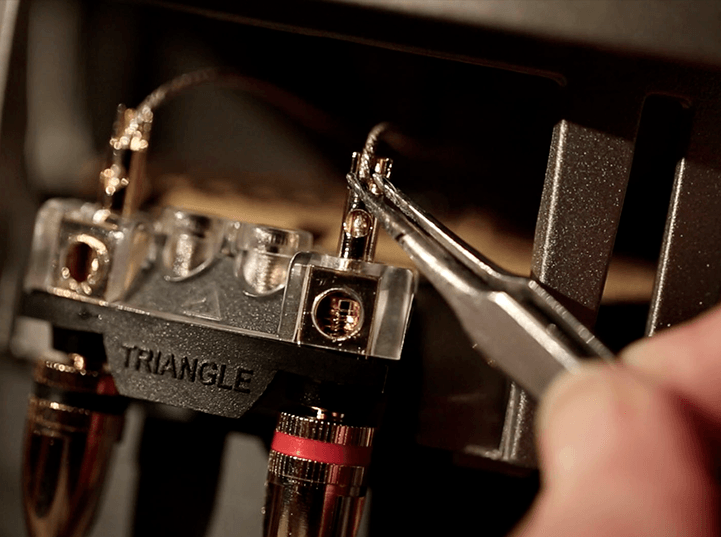

From the loudspeakers, through the filtering, the terminal block and the wiring, everything has been designed for high performance.

DEsign

Multiple and long researches on the materials to be used and the finishes to be combined make it possible to offer our ranges a timeless and modern aesthetic at the same time.

Meticulous work to offer a noble and unique product expressing the TRIANGLE character.

ASSEMBLY & MOUNTING

The parts are manufactured and assembled with millimeter precision to offer an irreproachable finish and acoustics. The engineers in charge of development work closely with the workshop to offer a high quality product.

SPEAKERS

The loudspeakers are assembled in-house to ensure optimum build quality and virtually zero dispersion, and are low-frequency generator tested to detect any unwanted noise.

contrOl & QUALITY

Numerous acoustic tests are carried out throughout the process to ensure the compliance of each component. Each speaker is tested in the anechoic chamber, a sample is then taken and listened to in the auditorium.

OUR RANGES MADE IN FRANCE

40th Anniversary

Legacy & modernity

Signature

The Art of Sound with a french touch

Magellan

The ultimate sound restitution

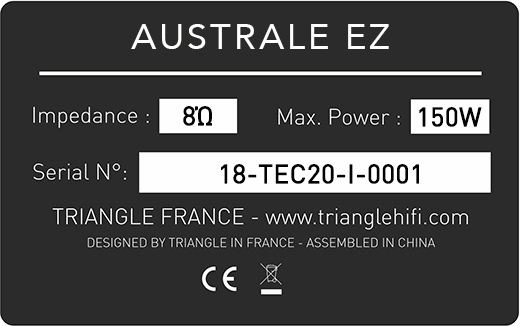

Where can I find my serial number ?

Serial number is at the back of your product.

Serial number maybe like this :

18-TEC20-I-0001

This site uses cookies to provide you with a great user experience. By using our website, you accept our cookie policy. More details